Did you know that 70% of all skillets sold in the U.S. are nonstick? This fact underscores the widespread adoption of nonstick Teflon coating in kitchens across the nation. But have you ever wondered the science behind this phenomenon?

The allure of Teflon lies in its scientific intricacies. Known officially as polytetrafluoroethylene (PTFE), this coating was first patented in 1941. Its applications extend far beyond cookware, finding its way into waterproof clothing and even spacesuits due to its unique properties.

What sets Teflon apart is its extraordinary slipperiness. With a coefficient of friction as low as 0.02, it rivals the smoothness of wet ice on wet ice. This attribute ensures that food glides off the pan effortlessly, simplifying cooking and cleaning processes.

The narrative of Teflon is not solely about its nonstick prowess. The history of Teflon production has been marked by both progress and controversy, particularly regarding the chemical PFOA. However, since 2013, Chemours has removed PFOA from their Teflon production, ensuring the safety of modern cookware.

Key Takeaways

- Teflon is the brand name for PTFE, a nonstick coating

- 70% of skillets sold in the U.S. are nonstick

- PTFE has an incredibly low coefficient of friction (0.02)

- Modern Teflon cookware is PFOA-free since 2013

- Teflon’s uses extend beyond cookware to various applications

The Miraculous Discovery of PTFE

PTFE, known as Teflon, has an intriguing origin story. Its creation is a testament to how unexpected events can lead to groundbreaking inventions. Let’s look at the journey of this transformative substance.

Accidental Invention in the 1930s

In 1938, a laboratory mishap led to the invention of PTFE. Roy Plunkett, a DuPont chemist, was experimenting with refrigerants when he discovered a slippery, waxy substance. This chance finding would significantly alter the cookware industry.

From Lab Accident to Household Name

The transition from laboratory error to common household item was not immediate. DuPont recognized the potential of this material and began refining it for various uses. By the 1960s, Teflon-coated cookware entered the market, transforming cooking and cleaning practices.

Chemours and the Teflon Brand

Today, Chemours, a DuPont spinoff, owns the Teflon brand. They continue to develop PTFE-based products, extending its applications beyond the kitchen. Teflon’s history is complex, with environmental concerns prompting changes in production.

| Year | Event | Impact |

|---|---|---|

| 1938 | PTFE discovered | New material with unique properties identified |

| 1960s | Teflon cookware introduced | Revolutionized cooking and cleaning |

| 2015 | Chemours spun off from DuPont | New company takes over Teflon brand |

What is Teflon Made Of?

Teflon is primarily composed of polytetrafluoroethylene, or PTFE for short. This fluoropolymer boasts properties ideal for nonstick uses.

The Magic of PTFE

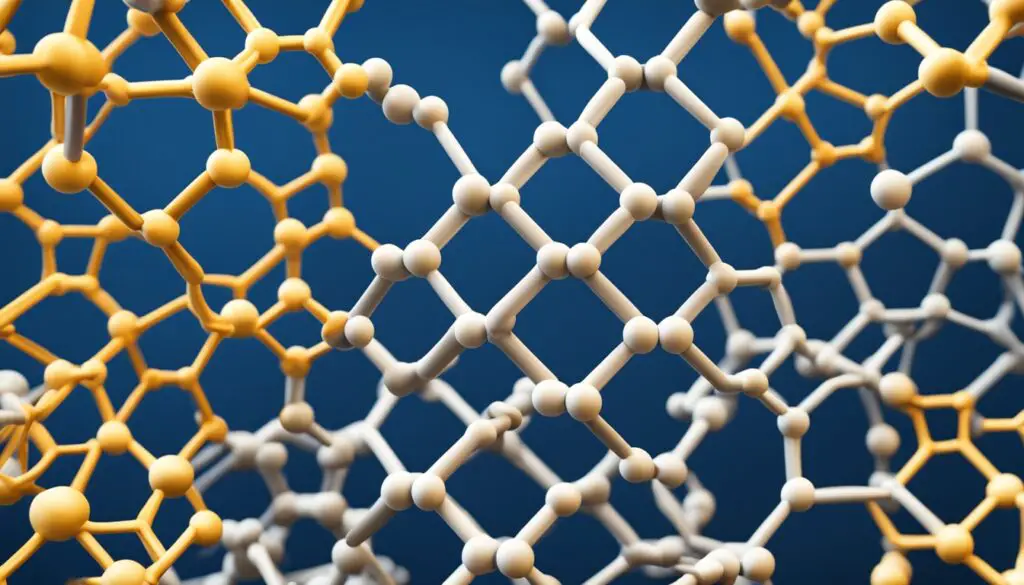

PTFE, a synthetic fluoropolymer, underpins Teflon. Its chemical makeup is responsible for the nonstick nature of Teflon. Composed of carbon and fluorine atoms, PTFE molecules form a surface that repels a wide array of substances.

Nonstick Behavior Explained

The nonstick attributes of PTFE are rooted in its distinct chemical structure. The fluorine atoms surrounding the carbon backbone yield a low-energy surface. This surface characteristic makes it challenging for substances like food or water to adhere to it. Consequently, Teflon-coated pans are renowned for their ease of cleaning and cooking.

| Property | Effect |

|---|---|

| Low surface energy | Repels most substances |

| Strong C-F bonds | Resists chemical breakdown |

| Smooth molecular structure | Prevents adhesion |

The Science of Nonstick Surfaces

Nonstick surfaces are a complex interplay of surface energy and molecular structure. At the forefront is Teflon, scientifically known as polytetrafluoroethylene (PTFE). Its exceptional slickness is unparalleled, boasting a friction coefficient of just 0.02.

The Role of Low Surface Energy

PTFE’s nonstick properties stem from its low surface energy. This energy level prevents it from forming bonds with other materials. Consequently, your eggs effortlessly slide off the pan.

Fluorine: The Key to Teflon’s Slippery Nature

Fluorine atoms are the cornerstone of Teflon’s nonstick prowess. They form a protective barrier around the carbon backbone of PTFE. This shield repels almost all substances, making it incredibly slippery.

Molecular Structure of PTFE

PTFE’s molecular structure is comprised of a chain of carbon atoms. Each carbon atom is flanked by fluorine atoms. This unique arrangement is the source of PTFE’s remarkable properties.

How Fluorine Atoms Repel Other Materials

The fluorine atoms in PTFE create a shield that repels various substances. Water, oil, and even sticky foods are repelled by this material. PTFE’s durability allows it to withstand extreme temperatures, from -328°F to 500°F, without degradation.

| Property | PTFE (Teflon) | Ceramic Coating |

|---|---|---|

| Temperature Resistance | Up to 500°F | Up to 700°F |

| Friction Coefficient | 0.02 | 0.20-0.30 |

| Market Share (US) | 70% of skillets | Growing alternative |

Manufacturing Process of Teflon Coatings

<

<

The Teflon coating process initiates with surface preparation. This involves grit blasting to eliminate contaminants and enhance adhesion. Following this, the coating application commences. Various methods are employed in Teflon manufacturing:

- Compressed air spray equipment

- Electrostatic coating

- Powder coating machines

Each technique offers distinct benefits. Compressed air spraying delivers a uniform coat with a high-gloss finish. Electrostatic coating facilitates quicker application and superior results, albeit requiring specialized knowledge. Powder coating is ideal for specific materials.

The concluding step is curing. The Teflon-coated items are subjected to high temperatures in a curing oven. This process ensures a refined surface finish and secures the non-stick properties.

It’s important to note that contemporary Teflon production avoids PFOA, addressing health worries linked to earlier methods. This shift towards safety has transformed the industry.

| Coating Method | Advantages | Challenges |

|---|---|---|

| Compressed Air Spray | Even coat, glossy finish | Manual application |

| Electrostatic Coating | Fast application, excellent results | Requires expertise |

| Powder Coating | Suitable for certain materials | Limited application range |

Applying Teflon to Cookware: A Step-by-Step Guide

The Teflon application process is more than just a simple spray job; it’s a detailed procedure that keeps our pans nonstick for years. Let’s look at the steps in this intriguing cookware coating process.

Liquid Coating Application

The process starts with a liquid Teflon mixture. This blend is applied to the metal pan’s surface with precision. Each layer is spread evenly, a crucial step for the product’s durability.

Multiple Layer Technique

One layer isn’t enough for quality cookware. Typically, two or three layers of Teflon coating are applied. Each layer has a role, from bonding with the metal to creating a smooth finish. This method ensures Teflon-coated pans last longer than ceramic-coated ones.

High-Temperature Baking Process

The final step is the high-temperature baking. This process, reaching up to 260°C (500°F), removes excess liquid and bonds the coating to the metal. It’s this step that gives Teflon-coated cookware its renowned durability and nonstick properties.

Why Food Doesn’t Stick to Teflon-Coated Surfaces?

The way food effortlessly slides off Teflon-coated cookware is truly astounding. Let’s look at the science behind this phenomenon and compare it with other cooking surfaces.

The Secret Behind Nonstick Properties

Teflon’s nonstick properties stem from its unique molecular structure. This coating boasts a low surface energy, preventing food molecules from adhering to it. Consequently, your eggs slide off effortlessly, unlike on other surfaces.

Food Interaction with Different Surfaces

When cooking, food interacts uniquely with various surfaces. Let’s examine how food behaves on Teflon, cast iron, and stainless steel:

| Surface | Food Interaction | Nonstick Level |

|---|---|---|

| Teflon | Minimal adhesion | High |

| Cast Iron | Forms a natural nonstick layer over time | Medium |

| Stainless Steel | Food can stick without proper preheating | Low |

While Teflon excels in nonstick properties, some opt for ceramic cookware for its safety and health benefits. Cast iron and stainless steel, with their distinct cooking techniques, can also yield excellent results with practice.

The Role of PTFE in Nonstick Performance

PTFE revolutionizes nonstick performance. Its fluoropolymer properties are truly remarkable. With a surface energy of 18-19 Dyne/cm, PTFE ensures food doesn’t stick. This is starkly different from metals, which have surface energies of 800-1000 Dyne/cm.

The nonstick properties of PTFE stem from its molecular structure. It’s loaded with fluorine atoms, creating a slippery barrier. This barrier is why your eggs slide effortlessly off a Teflon-coated pan.

PTFE’s benefits extend far beyond preventing breakfast from sticking. Its temperature range (-160°C to 260°C) makes it versatile across industries. From bakeware to automotive parts, PTFE coatings are unparalleled in their versatility.

Interestingly, PTFE represents nearly 50% of all fluoropolymers produced. Its applications stretch beyond cookware. Essential in aerospace and computer applications, PTFE is vital for wiring due to its dielectric properties. These properties make it perfect for hook-up wires and coaxial cables.

PTFE’s nonstick performance transcends the kitchen. In industrial settings, it surpasses materials like acetal and nylon for components needing smooth movement. Gears, bearings, and slide plates all benefit from PTFE’s low friction properties.

Teflon Without PFOA: A Safer Alternative

The nonstick cookware industry has undergone a significant transformation. Today, PFOA-free Teflon dominates the market, driven by health and environmental concerns. This shift has profoundly impacted consumer safety.

Chemours’ Commitment to PFOA-Free Production

In 2013, Chemours, the entity behind Teflon, made a groundbreaking decision. They eliminated PFOA from all Teflon products, a move influenced by extensive research and growing public awareness. The PFOA Stewardship Program, spearheaded by the EPA, played a pivotal role in this transition. By 2015, the industry had fully phased out PFOA.

Understanding PFOA and Its Concerns

PFOA, a former essential ingredient in Teflon, has been linked to numerous health issues. These include thyroid disorders and certain cancers. A landmark 1999 study detected PFOA in 98% of Americans’ blood, prompting a demand for safer alternatives.

| Health Concerns | PFOA Exposure | Safer Alternatives |

|---|---|---|

| Thyroid disorders | 98% of Americans (1999) | Ceramic cookware |

| Chronic kidney disease | Environmental exposure | Stainless steel |

| Liver disease | Pre-2013 Teflon products | Cast iron |

| Testicular cancer | Overheated Teflon fumes | Silicone cookware |

Techniques for Making Teflon Stick to Surfaces

Despite its renowned nonstick nature, manufacturers have devised smart ways to ensure Teflon adheres well to cookware and other items. These techniques are essential for creating coatings that last a long time.

Sintering is a favored method. It involves roughening the pan’s surface, applying Teflon, and heating the layers for adhesion. At high temperatures, the Teflon melts slightly, bonding with the base material. Ceramic waffle makers employ similar strategies to ensure their coatings stick well.

Plasma treatment is another method. It uses ion bombardment in a vacuum to break Teflon’s strong fluorine bonds. By replacing these bonds with oxygen atoms, a stronger adhesion between Teflon and the base material is achieved.

Chemical modification is a third effective technique. It alters Teflon’s surface chemistry, making it more receptive to bonding with other materials. This approach is particularly beneficial for uses beyond cookware, such as in medical devices or industrial equipment.

| Technique | Pros | Cons |

|---|---|---|

| Sintering | Effective for cookware, durable | Requires high temperatures |

| Plasma Treatment | Creates strong bonds, versatile | Complex equipment needed |

| Chemical Modification | Suitable for various applications | May alter some Teflon properties |

Sintering: The Heat and Pressure Method

Sintering is essential for making Teflon adhere to surfaces. This method, which involves heat treatment, is crucial for Teflon adhesion. The process heats Teflon from room temperature to between 685° and 720°F (363° to 382°C).

Process Explanation

During sintering, Teflon particles are heated and pressed onto a surface. This method is crucial for enhancing Teflon’s physical properties. It ensures the material has specific density, tensile strength, and elongation. PTFE sintering furnaces are used to manufacture items like pipes, valves, and seals for the chemical industry.

Limitations of Sintering

Sintering is effective but has its limitations. Teflon decomposes at around 245°C to 280°C, releasing harmful substances like trifluoroacetic acid. This restricts its use in high-temperature settings. Also Teflon’s tendency to creep over time can cause leaks in certain applications.

| Sintering Process Benefits | Sintering Process Limitations |

|---|---|

| Improves physical properties | Temperature limitations (max ~250°C) |

| Enables diverse product manufacturing | Potential for material creep |

| Enhances corrosion resistance | Risk of decomposition at high temperatures |

| Allows for mass production | Requires precise temperature control |

Chemical Modification for Better Adhesion

Chemical modification significantly enhances Teflon adhesion, altering its surface chemistry for stronger bonds with other materials. This results in a nonstick coating that lasts longer, ideal for diverse uses.

Surface treatment techniques, such as chemical etching, are crucial for boosting Teflon adhesion. This method modifies the PTFE surface without affecting its essential properties. It’s especially beneficial for industrial settings where robust bonding is essential.

The process of chemical modification involves exposing Teflon to specific reagents. These reagents break down the fluorine bonds, creating sites for enhanced adhesion. Interestingly, etched PTFE has a short shelf life and must be stored in a controlled environment to maintain its properties.

Industrial adhesives like epoxies and polyurethanes adhere exceptionally well to etched PTFE surfaces. This versatility makes Teflon suitable for applications beyond cookware, including chemical processing, aerospace electronics, and medical equipment.

When selecting kitchen appliances, opt for those with advanced nonstick coatings. The Euro Cuisine WM520 Ceramic Heart Waffle is a prime example of a product that leverages modern nonstick technology safely and conveniently, without Teflon.

Plasma Treatment: Breaking Fluorine Bonds

Plasma treatment is revolutionizing the adhesion of Teflon. This process significantly enhances the surface of PTFE, making it more receptive to bonding. Let’s look at the intricacies of plasma treatment and its effects on Teflon.

Ion Bombardment in High Vacuum

The plasma treatment initiates with ion bombardment within a high vacuum. An electric field propels ions towards the Teflon, breaking its fluorine bonds. These bonds are crucial for Teflon’s non-stick nature.

Plasma treatment profoundly alters PTFE’s surface. For instance, using N2 gas can diminish PTFE’s hydrophobicity in mere minutes. The water contact angle decreases from 141.9° to 109.5°, signaling enhanced wettability.

Oxygen Substitution for Stronger Adhesion

Post-fluorine bond disruption, oxygen molecules bond with the exposed carbon atoms. This oxygen substitution renders the surface more reactive, setting the stage for stronger material bonds. Consequently, Teflon surfaces exhibit enhanced bonding capabilities.

| Treatment Type | Duration | Effect |

|---|---|---|

| N2 Plasma | 2 minutes | Reduced hydrophobicity |

| Ar Plasma | 20 minutes | 8x increase in photocatalytic activity |

| H2O Plasma | Varies | Superhydrophilic surface |

Reducing Agents: Another Approach to Modification

Chemical modification employs reducing agents, which are vital in altering Teflon’s surface properties. Let’s examine the mechanics behind this process and its efficacy.

Reducing agents sever the strong fluorine-carbon bonds on Teflon’s surface. This action yields carbon radicals, extremely reactive entities. These radicals subsequently form unsaturated hydrocarbons, leading to a sticky surface that adheres well to materials such as metal cookware.

The role of reducing agents in enhancing Teflon adhesion is pivotal for cookware production. By adopting this method, manufacturers can make durable, long-lasting nonstick surfaces. This addresses prevalent concerns over Teflon coating longevity.

Let’s dissect the chemical modification process with reducing agents:

- Application of reducing agents to the Teflon surface

- Breaking of fluorine-carbon bonds

- Formation of carbon radicals

- Creation of unsaturated hydrocarbons

- Enhanced adhesion to metal surfaces

This novel approach to Teflon modification heralds new possibilities for nonstick cookware performance and longevity. As ongoing research advances, we may witness even more sophisticated techniques for augmenting Teflon adhesion in the future.

| Aspect | Traditional Teflon | Chemically Modified Teflon |

|---|---|---|

| Surface Properties | Smooth, non-reactive | Reactive, with unsaturated hydrocarbons |

| Adhesion to Metal | Limited | Enhanced |

| Durability | Prone to peeling | Improved longevity |

| Manufacturing Process | Standard application | Includes reducing agent treatment |

Beyond Cookware: Diverse Applications of Teflon

While it’s commonly linked to nonstick pans, Teflon’s uses stretch far beyond the kitchen. From campfire cast iron waffle irons to advanced technologies, Teflon’s distinct properties are crucial in various sectors.

Teflon’s waterproof coatings have transformed the textile industry. Did you know that Teflon EcoElite™ incorporates 60% renewably sourced materials? This green choice attracts the 66% of consumers ready to spend more on ethical products.

In the aerospace field, Teflon has been transformative. Its ability to withstand high temperatures makes it ideal for airplane components. The airline sector has utilized Teflon coatings for years, showcasing its enduring quality and dependability.

Teflon in Technology and Medicine

PTFE’s low friction traits are perfect for data communication cables. In medicine, Teflon coatings on implants and devices enhance their compatibility with the body and performance.

| Industry | Teflon Application | Key Benefit |

|---|---|---|

| Textiles | Waterproof clothing | Water and stain repellent |

| Aerospace | Spacemake components | Heat resistance |

| Technology | Cable insulation | Low friction |

| Medicine | Implant coatings | Biocompatibility |

Maintaining and Caring for Teflon-Coated Surfaces

Understanding the importance of Teflon maintenance is crucial for your cookware’s longevity. To maintain your nonstick surface, clean it with hot, soapy water and a soft cloth. Always handwash your pans to shield the coating from harsh detergents and extreme temperatures.

For the best care, avoid using metal utensils or abrasive scrubbers. Instead, choose silicone or wooden tools to prevent scratches. When cooking, use low or medium heat settings. This approach not only preserves the nonstick coating but also ensures even browning and enhances flavors. It’s a strategy that benefits both taste and nonstick surface longevity.

Seasoning new pans before their first use can significantly improve their performance. Start by washing, drying, and lightly coating with oil. For tough residues, a paste made from baking soda and water works well. Gently scrub without damaging the surface.